Hydro Dipping.Printing Designs With Water.

What Is Hydro Dipping?

Hydro dipping, or Water Transfer Printing refers to the process of printing designs onto 3D objects using special vinyl designs, and water.

This dipping process allows you to “print” almost any design onto almost any object you want.

Examples of Objects You Can Hydro Dip:

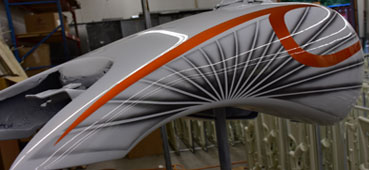

- Motorcycle Parts (Gas Tank/Fairing/Parts)

- Sporting Equipment (Guns/Cross Bows/Rifles)

- Musical Instruments (Guitars/Drums)

- Auto, Truck, RV Parts (Rims/Panels/Parts)

- Furniture

Note: If you can paint it, you can most likely hydro dip it!

How Does Hydro Dipping Work?

This dipping process is a printing technique that starts with laying a poly vinyl film with a design on it into a large dipping tank of water.

Once the vinyl film design is floating on the water, a chemical activator is then sprayed over the surface area of the water.

This chemical activator makes the design from the vinyl film become floating ink.

After the chemical activator is applied, your object is then slowing dipped into the water, therefore transferring the vinyl print design onto your object.

Finally, after your object is dipped a clear coat finish is applied in order to protect the finish.

The clear coat that is applied comes in a matte, glossy, or satin finish.

Note: The Clear Coat Is About As Durable As Clear Coating Used In The Automotive Industry.

What Are The Uses For Hydro Dipping?

This is a versatile process that is used to print custom designs onto most objects.

The unique vinyl film allows you to finish your projects with an awesome design, instead of a boring paint job.

Camouflage, fiberglass, floral, flames, skulls, and even custom patterns can be accomplished when you hydro dip it.

Not only can you use almost any design, but you can also hydro dip almost any object.

Common Materials We Hydro Dip:

- Plastics

- Fiberglass

- Wood

- Metals

- Glass